DEWATERING

Jual Filter Press

Filter press disebut sebagai separation equipment yang bekerja dengan sistem batching, dimana slurry dipompakan tidak secara continues namun secara berkala batch demi batch.

Produk-produk yang kami buat Antara lain :

- Filter Press

- Dust Collector

- Spray Dryer

- Rotary Dryer

- Screw Press

- Chimney/Wet Scrubber

- Dissolved Air Flotation

- Dan berbagai Peralatan lainnya.

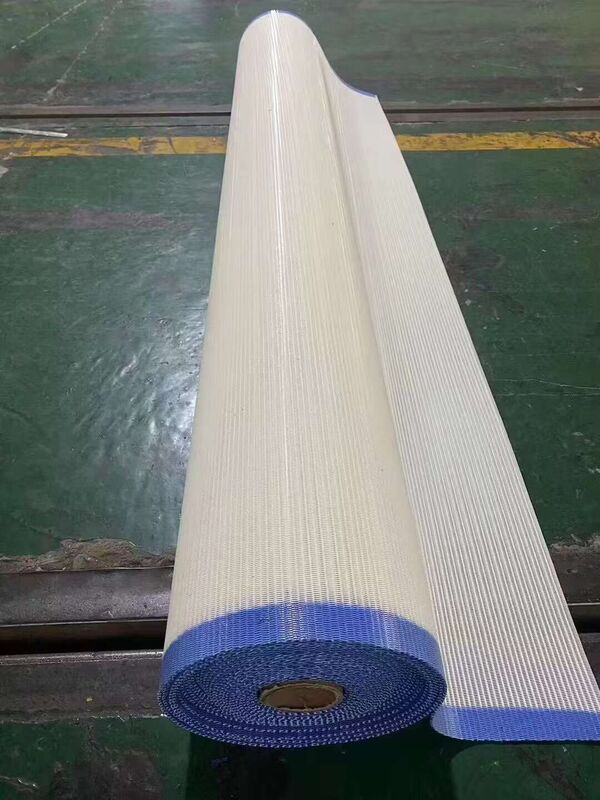

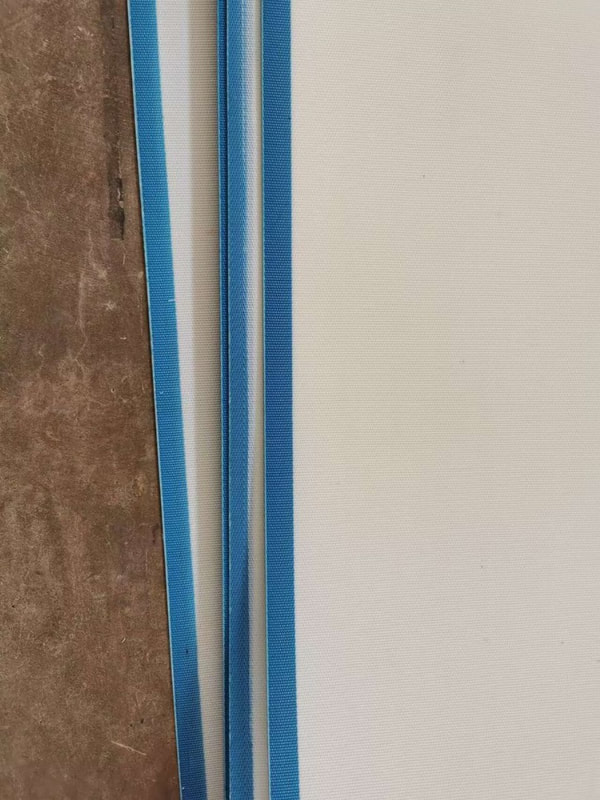

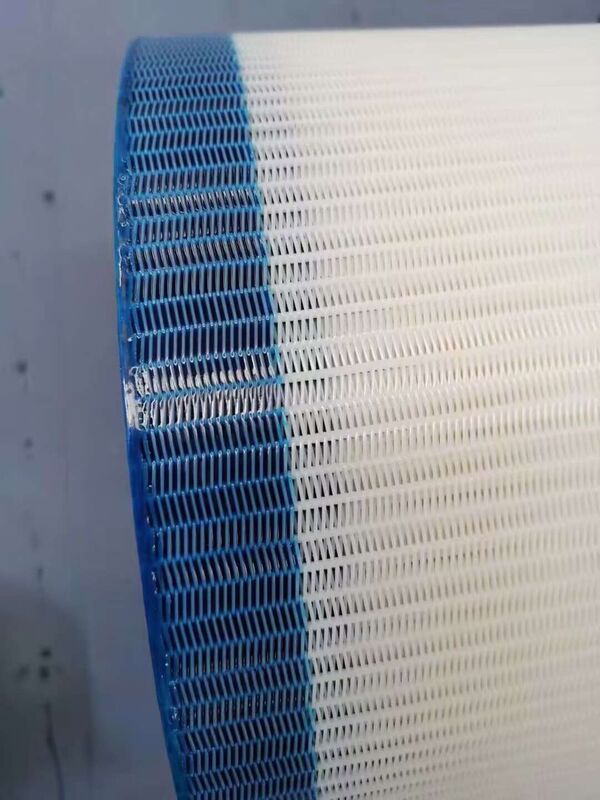

wire filter cloth belt press

Polyester Fabric Sludge Dewatering Filter Mesh Conveyor Belt for Press

1. 100% Polyester Fabric Sludge Dewatering Filter Mesh Conveyor Belt for Press Overview

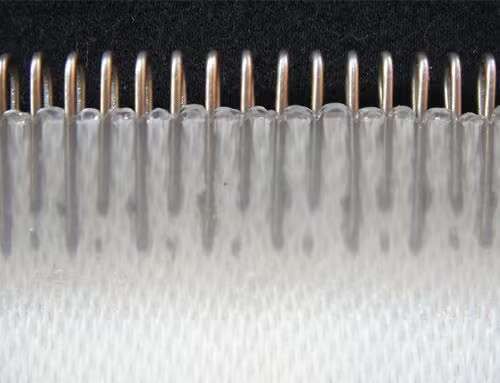

Polyester Filter Belts are specially designed woven mesh filter cloth for the belt press filters, it’s a circuit belt fabric connected by SS clipper seam to be able to work continuously.

The filter belts is a sturdy fabric made out by high viscosity polyester monofilament yarn on heavy-duty weaving looms and being heat set. PFM’s choose superior polyester monofilament yarn, weaving by advanced looms, excellent thermal treatment, all these makes our polyester filter belts in precise aperture, good transverse stability, lengthways flexibility, excellent mechanical strength and stability in shape and dimension.

Polyester sludge dewatering vacuum belt filter press dryer fabrics Features:

The woven polyester filter belts as the belt filter cloth, plays a crucial part in the belt filter press, etc, as it determines the actual output and efficiency of the filtration process.

The special twill weave ensures precise filtration results, and smooth surface makes filter cake comes off easily, the high-quality polyester monofilament yarn makes our woven mesh filter belt fabrics being chemically-resistant, good strength could withstand the greatest mechanical stresses and long service life.

Food contact regulations compliant

Flexible and stable in dimension, accurate size and non-deforming

Excellent chemical stability, Synthetic Fiber Chemical Properties Table

Abrasion-resistance, long service life

High-temperature resistance, up to 150 degrees

Excellent filtration result

Smooth surface, filter cake release easily

Large width up to 6.5M

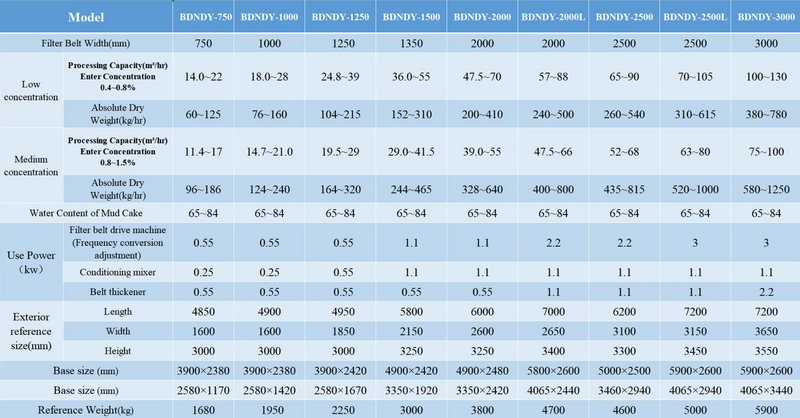

Continuous Gravity Belt Filter Press for Sewage Water Plant Sludge Dewatering

Applications

Sludge dewatering machine is suitable for the sewage treatment plant, waterworks and paper making,printing and dyeing,leather,chemical industry,slaughtering,pharmacy,electroplating,metallurgy,building materials,brewing,food and other industries after the wastewater treatment process of sludge dewatering.

Features

1.Compact structure, beautiful appearance.

2.The concentration and dehydration rate is high,and the solid content of the mud cake is high.

3.Automatic control,operating intensity is extremely low,reliable operation.

4.Cover an area of an area small, continuous work,litle noise.

5.Low energy consumption and long service life

6.Economically reliable and with a wide range of applications

Working Principle

1. The entire working process of the BDNDY belt sludge thickening and dewatering integrated machine can be divided into four basic stages.1. Sludge flocculation: Before dewaterimg, sludge must first go through a focculation process.

Flocculation refers to the pretreatment ofsuspended solids with a floculant. A fter the flocculant and sludge are stired and mixed, the solid particles in the suspension system adhereand produce a coagulation phenomenon, thus separating the solid phase from the liquid phase. At the same time, a small amount of coagulantaid is added to improve the flocculation effect.

2. Gravity dewatering: To more efiectively reduce the fluidity of the sludge before presing, more free water must be removed. The rumnimgsection of the filter belt has an upward inclimation Angle. The fiction coeficients ofthe sludge, free water and the filter bel are difierent. Thesludge moves upward with the filter belt to remove the free water. The sludge combing device disperses the sludge and evenly distributes iton the surface of the filter belt, further enhancing the dewatering effect.

3. Pressing dewatering: After gravity dewatering, as the filter belt moves, it enters the wedge-shaped pressure section between the upper andlower filter belts for pre-pressing dewatering, and then enters the "s-shaped pressing zone". Due to the shear force generated by the sludgebending in multiple sections along with the filter belt, the firee water inside is squeezed out.

4. Filter belt cleaning: lt is composed of a spray nozzle, a cleaning water collection box and a cleaning cover, etc. When the filter bel of thebelt filter press moves, it continuously passes through the cleaning device and is impacted by the pressure water sprayed by the spraver. Thematerials remaining on the fiter belt are separated from the filter belt under the action of the pressure water, regenerating the filter belt andpreparing for the next dewatering process.

AIR POLUTION

Dust Collector

Dust collector bulk semen adalah alat yang digunakan untuk mengumpulkan debu yang dihasilkan selama proses penanganan semen curah. Alat ini penting untuk menjaga kebersihan lingkungan kerja dan mencegah polusi udara.

Bagaimana cara kerjanya:

Pengumpulan Debu: Udara yang mengandung debu dari proses penanganan semen curah dialirkan ke dalam dust collector.

Filtrasi: Udara kotor melewati filter khusus yang menangkap partikel debu.

Pembersihan Filter: Filter secara otomatis dibersihkan secara berkala untuk memastikan kinerja optimal.

Pengeluaran Udara Bersih: Udara bersih yang telah disaring dikeluarkan kembali ke lingkungan atau didaur ulang untuk digunakan kembali.

Manfaat Menggunakan Dust Collector Bulk Semen:

Kesehatan Pekerja: Melindungi pekerja dari paparan debu semen yang berbahaya bagi pernapasan.

Lingkungan Kerja Bersih: Menjaga kebersihan lingkungan kerja dan mengurangi risiko kecelakaan akibat lantai yang licin karena debu.

Kepatuhan Lingkungan: Memastikan industri semen mematuhi standar emisi udara yang ditetapkan oleh pemerintah.

Penghematan Energi: Beberapa dust collector dilengkapi dengan sistem resirkulasi udara yang dapat membantu menghemat energi.

Jenis-jenis Dust Collector Bulk Semen:

Bag Filter: Menggunakan kantong filter untuk menangkap debu.

Cartridge Filter: Menggunakan filter kartrid yang lebih efisien dan mudah diganti.

Cyclone: Menggunakan gaya sentrifugal untuk memisahkan debu dari udara.

Apakah Anda ingin tahu lebih banyak tentang dust collector bulk semen? Saya dapat membantu Anda menemukan informasi lebih lanjut atau rekomendasi produk yang sesuai dengan kebutuhan Anda.

filter bag dust collector

1. PTFE series filter is needle felt filter and film filter made of 100% PTFE fiber and fabric by the

special technology woven fabric ,mainly used in hazardous waste incineration, domestic waste

incineration production high temperature, high corrosion of flue gas treatment.

2. Using 100% PTFE fiber filter, can long-term stable and efficient work in high-strength rot

corrosion, high humidity, high temperature environment.

Filter catridge dust collector

filter bag dust filter

1.ISO9001:2008 Certified

This product is ISO9001:2008 certified, ensuring worldwide quality management standards are met, providing customers with assurance of high-quality products and services.

2.Versatile Application

The bag filter is specifically designed for bag house dust collector applications, suitable for various industries including machinery repair shops and energy & mining.

3.Robust Material Construction

Constructed from robust materials like polyester, nomex, PPS, PTFE, and FMS, these bag filters are engineered to withstand the rigors of industrial environments while offering maximum protection against dust and debris.

4.Customizable Package and Weight

Available in different weights ranging from 300gsm to 900gsm, these bag filters are ideal for applications requiring varying levels of filtration efficiency. The package size is 63*36*37cm and comes in a big carton with a plastic bag inside to protect the product during transportation.

5.Premium Filter Cloth

The premium filter cloth ensures optimal performance and reliability while maintaining a lower pressure drop, ensuring better system efficiency and reduced energy consumption. Additionally, a video outgoing-inspection and machinery test report are provided for added transparency and assurance.

MATERIAL HANDLING

belt Conveyor elektronic industri

PVC Conveyor

Conveyor untuk aplikasi beban ringan (light duty) dengan material PU atau PVC, warna hijau atau putih, tebal 1 mm, 2 mm , 3 mm, 4 mm dan 4.5 mm. Tersedia bottom fabric atau profil diamond untuk tebal tertentu. Dapat ditambahkan profil (K10/K13), sekat, dengan dimensi sesuai kebutuhan. Juga tersedia roughtop PVC.

gravity conveyor

Konveyor roller gravitasi memindahkan beban ke conveyor tanpa menggunakan sumber daya motor, biasanya menggunakan kemiringan dan gravitasi atau dengan didorong. Konveyor ini digunakan terutama untuk mengangkut karton, peti, paket dan / atau palet jarak yang lebih pendek. Gravity conveyor adalah salah satu peralatan yang paling umum ditemukan di banyak gudang.

almunium frame conveyor

Kategori Belt dan Conveyor / Conveyor Belt, ( Kami membuat conveyor dengan menggunakan frame berbahan alumunium yang proses lebih cepat , dan penampilan yang menarik serta berdaya guna tinggi.)

stainlis screw conveyor food grade

Screw conveyor, atau dikenal juga sebagai konveyor sekrup atau auger, adalah alat yang digunakan untuk memindahkan material curah seperti semen, pasir, biji-bijian, atau bahan lainnya. Alat ini bekerja dengan menggunakan prinsip sekrup Archimedes, di mana material didorong sepanjang tabung atau saluran oleh sekrup yang berputar.

Komponen Utama Screw Conveyor:

Sekrup (Screw/Auger): Bagian utama yang berputar dan mendorong material.

Tabung/Saluran (Trough/Tube): Tempat sekrup berputar dan material bergerak.

Motor Penggerak: Memberikan tenaga untuk memutar sekrup.

Bearing: Mendukung sekrup agar berputar dengan lancar.

Inlet dan Outlet: Tempat masuk dan keluarnya material.

Cara Kerja Screw Conveyor:

Material dimasukkan melalui inlet.

Sekrup yang berputar mendorong material sepanjang tabung.

Material bergerak secara terus-menerus hingga mencapai outlet.

Keunggulan Screw Conveyor:

Desain Sederhana: Mudah dioperasikan dan dirawat.

Serbaguna: Dapat digunakan untuk berbagai jenis material curah.

Efisien: Mampu memindahkan material dalam jumlah besar dengan cepat.

Fleksibel: Dapat dipasang secara horizontal, vertikal, atau miring.

Aplikasi Screw Conveyor:

Industri Semen: Memindahkan semen curah dari silo ke truk atau tempat penyimpanan lainnya.

Pertanian: Memindahkan biji-bijian, pakan ternak, atau pupuk.

Industri Makanan: Memindahkan bahan baku seperti tepung, gula, atau biji kopi.

Industri Kimia: Memindahkan bahan kimia bubuk atau granul.

Apakah Anda ingin tahu lebih banyak tentang screw conveyor? Saya dapat membantu Anda menemukan informasi lebih lanjut atau rekomendasi produk yang sesuai dengan kebutuhan Anda.

General Trading

9/16 Stainless Steel Waste Oil burner Nozzle, 60 Degree Full Cone Fuel burner Nozzle,Boiler Nozzle

Nozzle Pembakar Minyak Limbah Stainless Steel 9/16 ini terbuat dari Stainless Steel 304 yang tahan lama, tahan terhadap asam, alkali, dan korosi. Ini memiliki filter pasir tembaga, atomisasi yang sangat baik dengan sudut 80 derajat, dan disegel dengan paking tembaga untuk pemasangan mudah tanpa pita PTFE. Cocok untuk aplikasi metanol, air, dan bensin. Disertifikasi oleh CE, memastikan kepatuhan terhadap standar keselamatan UE dan menyediakan akses pasar.

Sorotan pemasok: Pemasok ini adalah produsen dan pedagang, menawarkan layanan kontrol kualitas, penyesuaian penuh termasuk opsi desain dan sampel,

Heavy Oil Burner Nozzle Mini Waste Oil and Methanol Burner for Restaurant Boiler Parts for Old Oil Burning

Heavy Oil Burner Nozzle Mini Waste Oil and Methanol Burner for Restaurant Boiler Parts for Old Oil Burning

Pressure Reducing Valve B-42 Gas Pipeline Pressure Regulating Valve Boiler Accessories

Product nameB-42Application Heating Boiler

Industrial Gas Burner Accessories

Applicable IndustriesBuilding Material Shops, Energy & Mining, Food & Beverage Factory, Manufacturing Plant, Other

Timing Belt Idler Pulley

Idlers S5M

Idlers for timing pulleys are an economy item, The price is cheaper than the standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Belt Width Used (mm.) : 4, 6, 10, 15, 20 and 25

● Belt Width Used (Inch.) : 0.19, 0.25, 0.31, 0.37, 0.5, 0.75 and 1

● Bearing Position : Central Single Bearing and Both Sides Bearing

● Shaped : With or without flanged

● Material :

Body and Flange : Aluminum Alloy

Bearing : Steel

● Surface treatment : Clear Anodized

[Application]

Idlers for timing pulleys are used to maintain proper tension and alignment in timing belt systems

Explosion Proof High Pressure 220V 380V 9-26 9-19 4-72 Belt Driven Centrifugal Blower Fan

centrifugal fan is mainly used for indoor ventilation general factory and large buildings or transport of air and other non

spontaneous, non explosive, volatile, not on the gas harmless, non corrosive to steel. But the transportation of gas not containing viscous substances,dust and hard particles contained no more than 150mg/m³,gas temperature should not exceed 80°C.

Applications

Sludge dewatering machine is suitable for the sewage treatment plant, waterworks and paper making,printing and dyeing,leather,chemical industry,slaughtering,pharmacy,electroplating,metallurgy,building materials,brewing,food and other industries after the wastewater treatment process of sludge dewatering.

Features1.Compact structure, beautiful appearance. 2.The concentration and dehydration rate is high,and the solid content of the mud cake is high. 3.Automatic control,operating intensity is extremely low,reliable operation. 4.Cover an area of an area small, continuous work,litle noise. 5.Low energy consumption and long service life 6.Economically reliable and with a wide range of applications

Working Principle1. The entire working process of the BDNDY belt sludge thickening and dewatering integrated machine can be divided into four basic stages.1. Sludge flocculation: Before dewaterimg, sludge must first go through a focculation process.

Flocculation refers to the pretreatment ofsuspended solids with a floculant. A fter the flocculant and sludge are stired and mixed, the solid particles in the suspension system adhereand produce a coagulation phenomenon, thus separating the solid phase from the liquid phase. At the same time, a small amount of coagulantaid is added to improve the flocculation effect. 2. Gravity dewatering: To more efiectively reduce the fluidity of the sludge before presing, more free water must be removed. The rumnimgsection of the filter belt has an upward inclimation Angle. The fiction coeficients ofthe sludge, free water and the filter bel are difierent. Thesludge moves upward with the filter belt to remove the free water. The sludge combing device disperses the sludge and evenly distributes iton the surface of the filter belt, further enhancing the dewatering effect.

3. Pressing dewatering: After gravity dewatering, as the filter belt moves, it enters the wedge-shaped pressure section between the upper andlower filter belts for pre-pressing dewatering, and then enters the "s-shaped pressing zone". Due to the shear force generated by the sludgebending in multiple sections along with the filter belt, the firee water inside is squeezed out.

4. Filter belt cleaning: lt is composed of a spray nozzle, a cleaning water collection box and a cleaning cover, etc. When the filter bel of thebelt filter press moves, it continuously passes through the cleaning device and is impacted by the pressure water sprayed by the spraver. Thematerials remaining on the fiter belt are separated from the filter belt under the action of the pressure water, regenerating the filter belt andpreparing for the next dewatering process.